Astronomers will soon have a new set of eyes to probe the far reaches of the universe, as the Giant Magellan Telescope’s fourth mirror begins the careful process from glass shards to an observatory’s mirror.

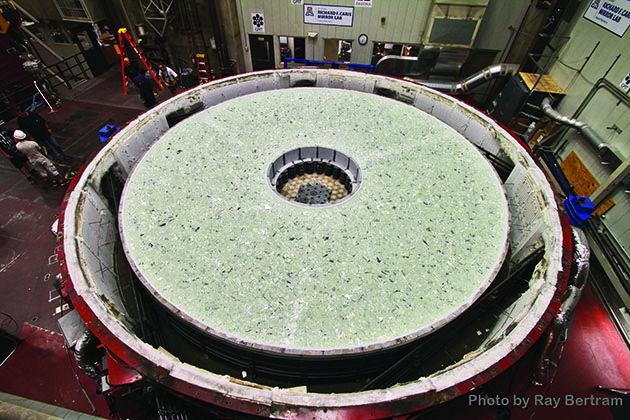

The GMT will be the largest optical telescope ever built when it sees first light in 2021. The fourth mirror of seven to be used in the GMT was cast on Sept. 18 at the University of Arizona, and is the final mirror needed for the telescope to become operational. This year will also mark the beginning of the creation for the physical site of the GMT in Chile.

Texas A&M and the University of Texas are two of 11 international partners who hope to construct the telescope high in the Chilean mountains, where the altitude reduces atmospheric interference and allows a clearer glimpse of the stars.

Nicholas Suntzeff, A&M astronomy and physics professor, said the beginning of the construction of the telescope will be celebrated by the “laying of the first stone,” a Chilean tradition that will take place in November. This tradition, as its name implies, is essentially a groundbreaking event that will mark the beginning of the assembly of the building that will become the GMT.

“[What] this represents is a major milestone for us because each mirror takes years to perfect,” said Taft Armandroff, director of the McDonald Observatory in Austin.

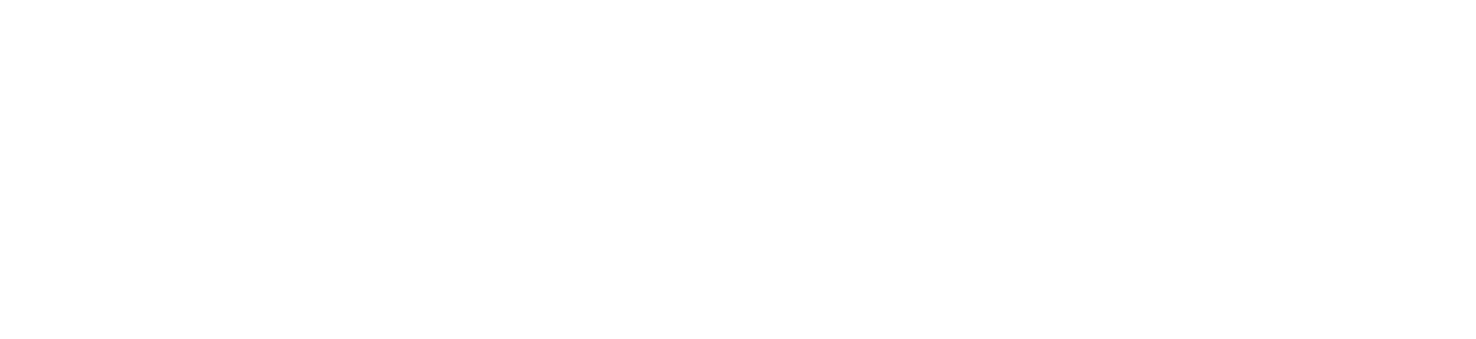

The process for creating each mirror is difficult in its own right, and it begins with the casting.

“The mirrors are cast in a rotating furnace and because of the forces on the glass, they are formed into a concave shape,” Armandroff said. “This makes the mirror much closer to its natural figure than if we had used a conventional furnace.”

This saves a substantial amount of money and time for each mirror.

The glass takes several months to cool, and once it is cool, finer and finer grits are used to grind the mirror into its final shape.

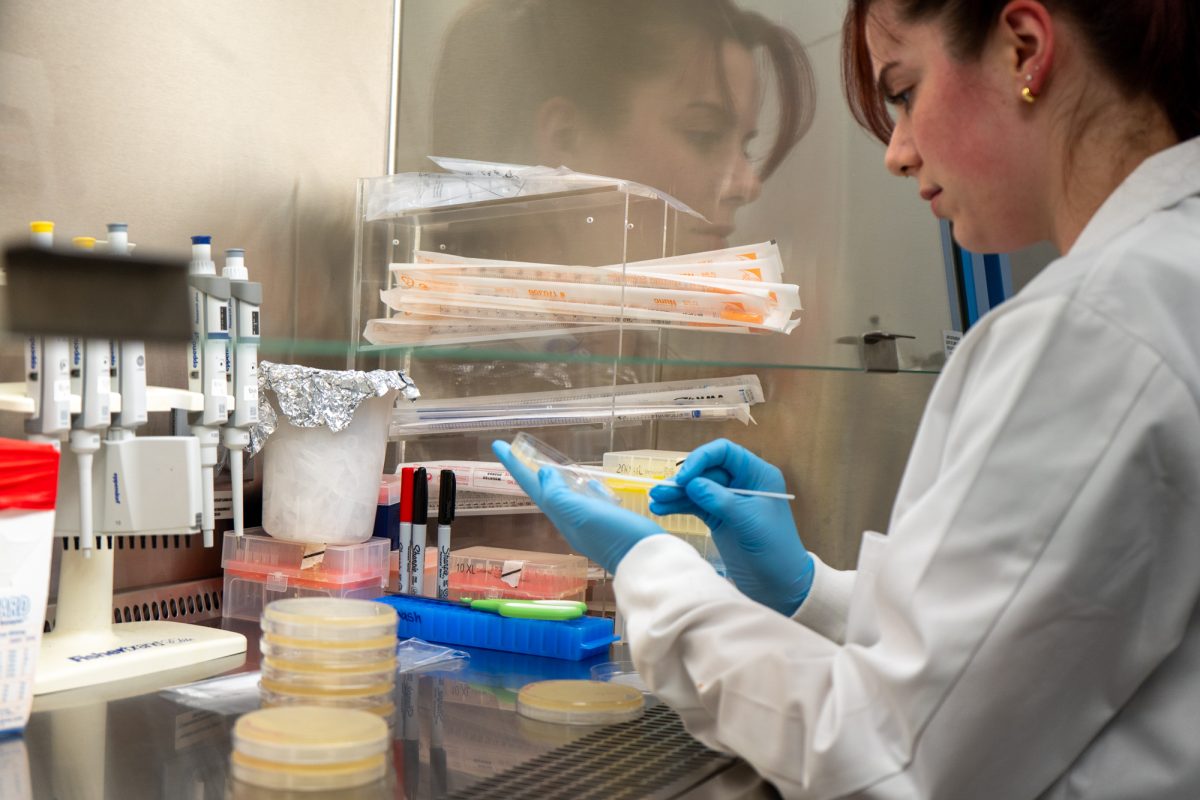

“The final polishing step is putting rouge, which is finely ground rust, on the mirror,” Suntzeff said. “A tool, which is another piece of glass, is placed on top of the rouge and gravity causes the rouge to produce a very smooth surface.”

The entire process can take well over a year. The work may seem excessive to the untrained eye, but the level of precision on the completed mirror is unparalleled.

“If you take this mirror, once it is finished, and stretch it all the way across the United States, it is so carefully polished that the largest ripple you will see is less than an inch,” Suntzeff said.

Closer to seeing farther

September 30, 2015

0

Donate to The Battalion

Your donation will support the student journalists of Texas A&M University - College Station. Your contribution will allow us to purchase equipment and cover our annual website hosting costs.

More to Discover