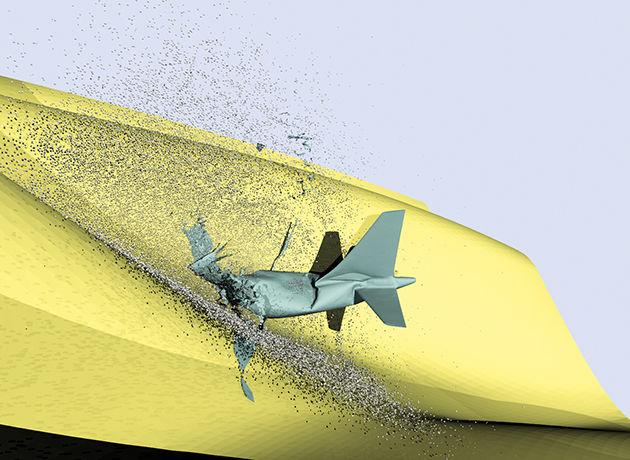

An international team of scientists and mathematicians have been working to reconstruct the crash of Germanwings flight 9525, which burst into thousands of pieces upon impact in the the French Alps in 2015, through complex computer simulations.

Led by A&M professor of mathematics Goong Chen, the team used a computer model to recreate the plane and the surrounding terrain, and then virtually crash the plane in different ways to try to determine which initial conditions most likely led to the observed debris pattern.

“Through mathematical modeling and the ensued supercomputing, we can visualize from the dynamic video animation how the airliner was totally destructed and fragmented,” Chen said. “This is like a ‘crime scene reenactment’ that is often critical in the investigation of any committed crime. But only computer simulation has made this possible, as physical experiments even with small scale models can be extremely expensive.”

According to Chen, the team had to collect data about the terrain from pictures provided by the French government, but that was all the contact they had with the crash site — the rest, including the plane model and everything related to it, was all done on the computer. By comparing debris patterns on site with those in the simulations, the team was able to determine with remarkable accuracy how the plane struck the mountain.

Cong Gu, assistant professor of mathematics, and a former graduate student of Chen’s who worked on the project with him, described the procedure for creating a model that can mimic the disintegration of a complex structure like a plane into millions of fragments.

“After we set up the basic models, we take into account the geometry of the aircraft, and the local situation in the mountains,” Gu said.

Gu said each piece of geometry on the plane was divided into hundreds of thousands of pieces, and the inside of the plane was populated with particles to represent its contents.

According to Darren Hartl, Class of 2003 and assistant professor of aerospace engineering who has worked with similar technology before, that is typical for simulations of this kind.

“The most common way of doing the kind of design and analysis that we’re doing is the finite element method,” Hartl said. “And what that basically entails, to a layman, is taking a very complex structure and breaking it up into very, very tiny, very regular shapes.”

According to Hartl, finite element analysis, or FEA, allows for precise programming of the plane’s contours, materials and densities.

“Every element can have its own material,” Hartl said. “One part is aluminum, another part is composite, the landing gear is steel, the aluminum for the top skin of the wing could be different than the aluminum for the bottom skin of the wing, and all that can be accounted for in FEA.”

However, this technology is not strictly limited to the occasional remote plane crash. According to Chen, it can be applied to any structure with the potential to crack or break into small pieces, and the simulations are usually used as a preventative measure rather than as an accident reconstruction tool.

“This kind of ‘software-engineering technology’ using impact and fracture mechanics modeling and supercomputing can be applied to many safety designs such as automobile crashworthiness, and the integrity/survivability of nuclear power plants under terrorists’ attacks by crashing airplanes,” Chen said.

In the future, Chen said he believes simulations like these could save humanity.

“Ironically, the survival of our human civilization may also hinge on impact mechanics and engineering, as a wayward asteroid hitting the earth could easily wipe out our human civilization,” Chen said. “We need to think about how to ‘diffuse’ such incoming asteroids by breaking them up before they get too close to Earth.”

A&M prof leads team of researchers to investigate Germanwings plane crash

March 20, 2017

0

Donate to The Battalion

Your donation will support the student journalists of Texas A&M University - College Station. Your contribution will allow us to purchase equipment and cover our annual website hosting costs.

More to Discover