During flight, airplanes experience significant loads and stresses, and over time these loads can lead to cracks forming in high-stress areas of planes.

In the past, these cracks were easy to detect because people smoked on planes — nicotine from the cigarettes got lodged in the cracks, allowing engineers to easily locate them. However, once smoking on planes was banned, the cracks became more elusive.

Darren Hartl, aerospace engineering professor, alongside his graduate student Brent Bielefeldt and a fellow mechanical engineering professor, Ibrahim Karaman, has been developing a new way to detect these cracks.

Hartl’s method aims to improve on the current system for checking for fractures, which is tedious and time-consuming.

“You walk into an American Airlines plane during a heavy check, it’s just green aluminum,” Hartl said. “And they’re down there, the mechanics, they’re crawling around with mirrors and flashlights and looking for cracks at critical places where they know that they will form.”

According to Hartl, this is not only terribly inefficient, but also very dangerous. Since the mechanics can’t scan every part of the plane, they have to focus on high-risk areas, and that means that if a crack forms somewhere else, it could go unnoticed until the next inspection, which could be years later.

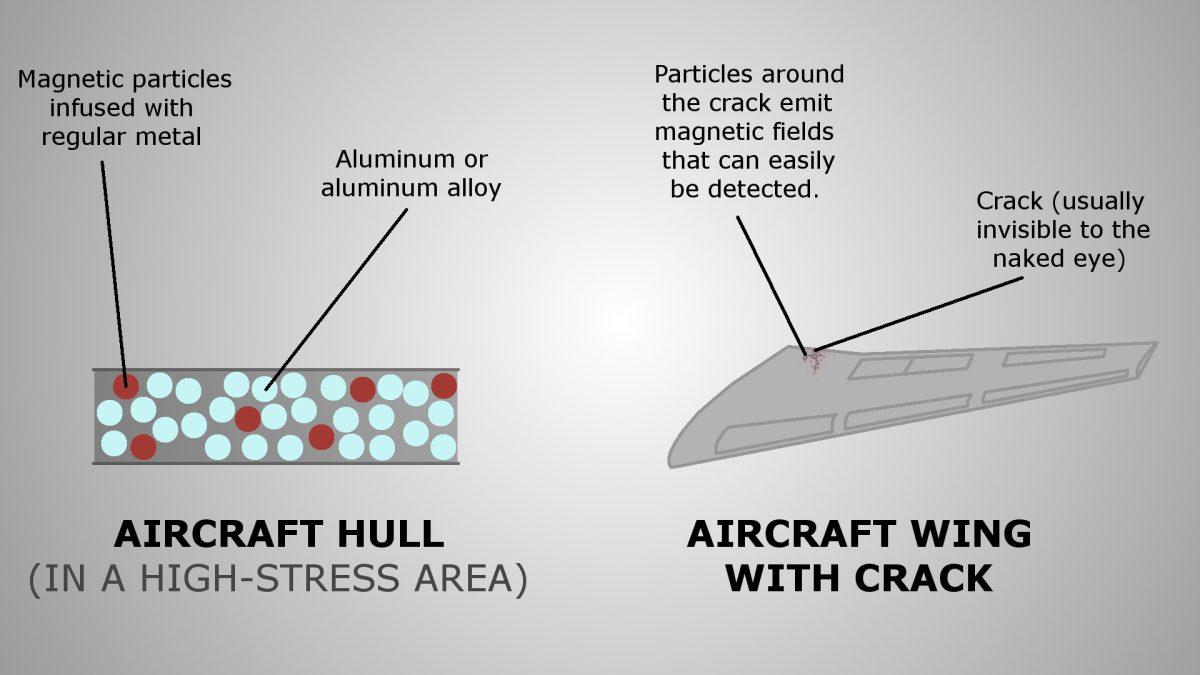

Hartl’s plan was to make detection a much easier process by adding special particles to the aluminum alloy that the aircraft is usually made of.

“What we wanted to use, a particle that shows both acoustic change or magnetic change,” Karaman said. “These particle materials are called magnetic shape memory alloys.”

According to Karaman, the molecules in a regular shape memory alloy change shape when a stress is applied to them — for example, a stress fracture in an airplane wing. By adding elements like cobalt and tin to a base of manganese and nickel, Karaman could elicit a unique magnetic signature from these particles whenever they came under stress.

Bielefeldt said the practical demonstration of this concept fell on him.

“If you consider you have an array of particles, and you know the response of each of them, you can plug that into a computer program and actually determine the location of the crackdown to within a couple of millimeters,” Bielefeldt said.

Bielefeldt’s work proved that the computer simulations of these particles were true to their actual behavior, and that if a crack was deliberately created in a particle-laden material, it could be detected and mapped very accurately.

Currently, though, these particles have limitations. According to Hartl, they need to be embedded in a homogenous metal or alloy to work properly. That means that any parts made with materials like carbon fibre cannot be outfitted with these particles.

“The forces inside the material are much more complicated in a composite,” Hartl said. “All the load is carried by the fibres. You never want to do anything to damage them, so you couldn’t put particles in the fibres.”

According to Hartl, there is still much work to be done, and, alongside Karaman, he is continuing to develop these particles for practical use by NASA, the military, and private contractors.

Karaman has also been looking into shape memory alloys and their applications outside of detecting damage in aircraft.

“People have shown that with mechanical stimulus, you can increase cell growth,” Karaman said. “If you take a piece of cartilage and you put mechanical stimulus on it constantly, it grows much faster.”

According to Karaman, it is possible to put collections of these shape memory alloy particles inside a human body to promote cell division in certain areas. And with these alloys being employed across many engineering fields, it would seem that Hartl’s research, which started out as a simple “what if” question, is far from over.

Detecting damage in aircraft

September 11, 2017

0

Donate to The Battalion

Your donation will support the student journalists of Texas A&M University - College Station. Your contribution will allow us to purchase equipment and cover our annual website hosting costs.

More to Discover