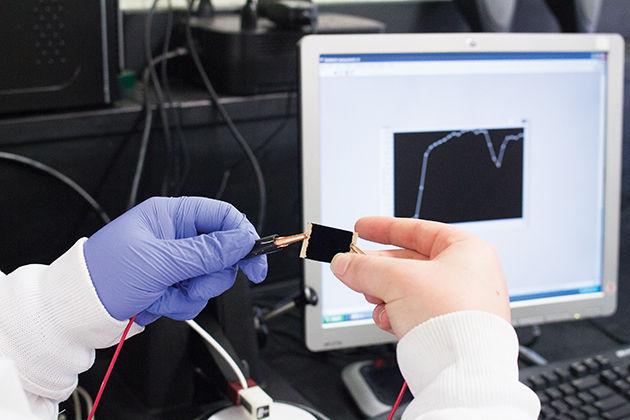

Cars, cell phones and humans all have one thing in common — they lose significant portions of energy through the production of excess heat. A&M researchers are attempting to capture this wasted heat as a new form of renewable energy.

“Thermoelectric” technology captures heat from mundane places such as car exhaust pipes and the human body to convert into usable energy. Essentially, if one side of a material is hotter than the other side, electricity will be generated.

At A&M, an engineering research group under mechanical engineering professor Jaime Grunlan is taking advantage of this property to create a material that functions like a battery any time one side is hotter than the other.

“We are attempting to use a thermoelectric coating technology that we can do at Texas A&M, that uses a thermal gradient across the surface to generate electricity,” Grunlan said.

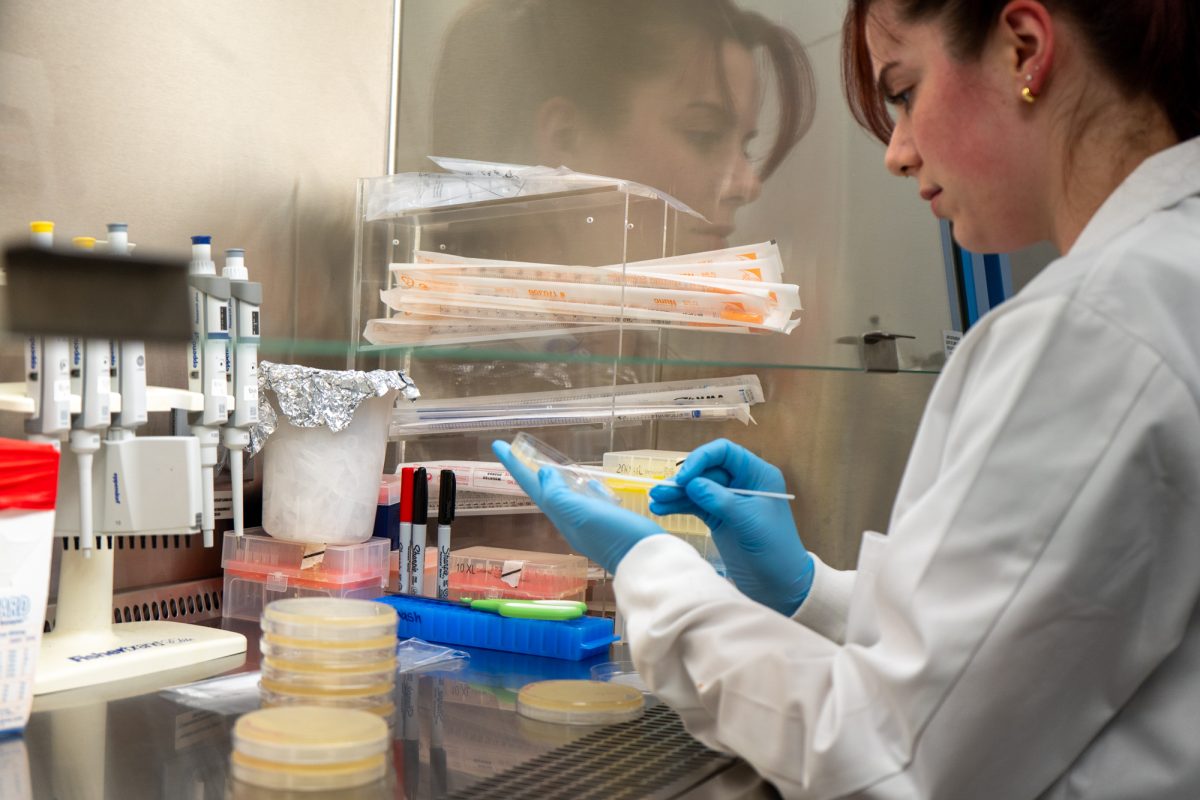

The technology’s applications are very extensive and can potentially be used anywhere a thermal gradient exists, said Alyssa John, a graduate student in Grunlan’s lab.

“These materials could be placed on the tailpipe of a car, and the temperature difference between the pipe and the air could be used to power electrical systems such as your stereo or lights,” John said. “That would then improve fuel economy by creating one less thing the engine has to provide power to.”

The technology could potentially be used to also recycle body heat. The human body wastes about 60 percent of its energy as unnecessary heat, Grunlan said. This phenomenon has led Grunlan’s lab to a potential partnership with a rugby team.

The Queensland Maroons, an Australian rugby team, came to College Station to visit with Grunlan to discuss using the technology in rugby jerseys. The head coach and some business partners flew into College Station for a few weeks to discuss using the technology to power sensors in their players’ jerseys.

“They wanted to power health sensors to put in the jersey,” Grunlan said. “Instead of having a battery, the shirt generates the voltage and sends the health information to the sidelines during the games.”

Negotiations with the team are still ongoing and the future of the healthmonitoring jersey is not set in stone, but the technology is still being improved upon with the goal of making it more efficient.

The relationship between a temperature gradient and usable electricity may seem hidden to most people, but it can be boiled down to a simple model, John said.

“When part of a material is hotter than another, electrons vibrating will work their way, or diffuse, into the colder part of the material, where the molecules and electrons can’t move as much,” John said. “Having more electrons on one side than the other gives your material a positive charge on the hot side and a negative charge on the cold side.”

The technology also has significant potential in large chemical production plants. The plants generate tremendous amounts of heat and reusing that heat could save plenty of energy.

“Some companies want to know if they could use this technology to paint a smokestack on a chemical plant,” Grunlan said. “They would be getting electricity for free if it was painted with thermoelectric technology.”

Powered by heat

October 21, 2015

Photo by Alexis Will

Thermoelectric

0

Donate to The Battalion

$90

$2500

Contributed

Our Goal

Your donation will support the student journalists of Texas A&M University - College Station. Your contribution will allow us to purchase equipment and cover our annual website hosting costs, in addition to paying freelance staffers for their work, travel costs for coverage and more!

More to Discover