A team of 21 senior mechanical engineering students will showcase the race car it built over a course of nine months as part of its senior capstone design course with the ultimate goal of a podium finish in June at the Formula SAE International event in Lincoln, Neb.

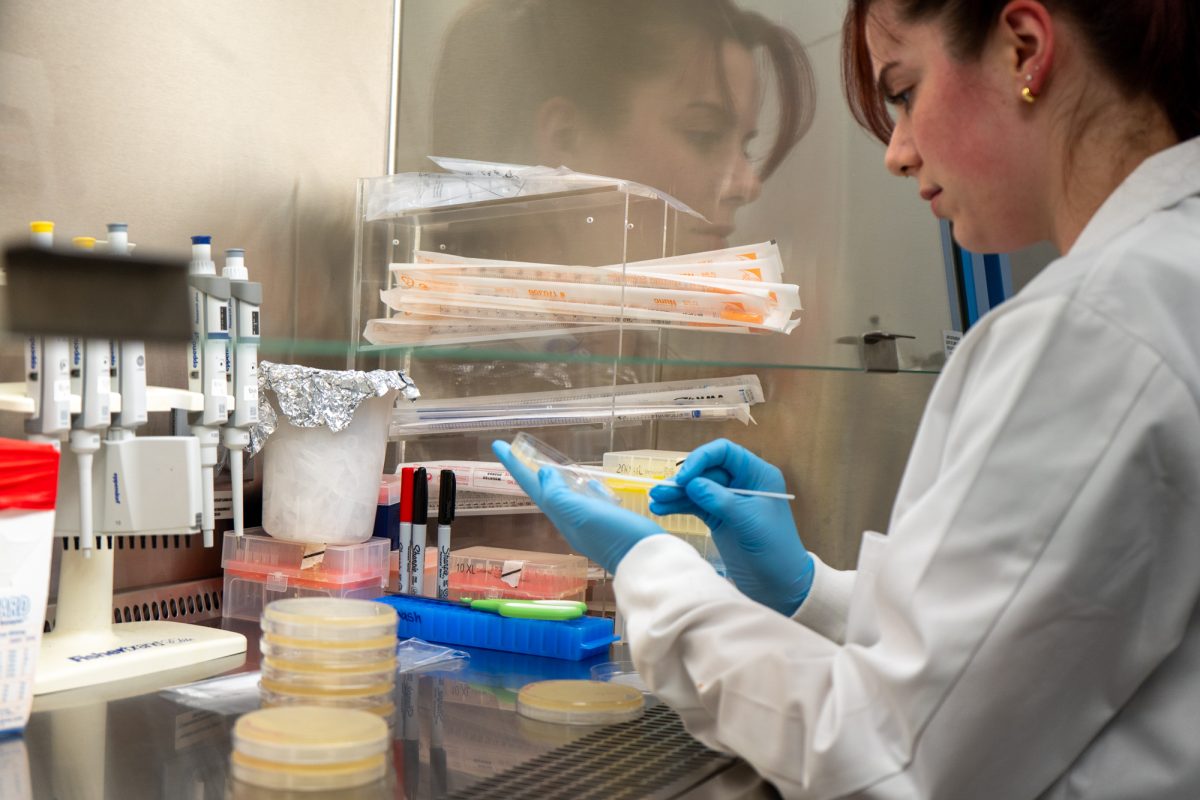

Formula SAE is a student design competition organized by SAE International, formerly Society of Automotive Engineers, in which teams are charged with designing, building, testing and competing with a prototype race car across a series of static and dynamic events. A&M students built the race car with most parts and systems manufactured in-house with a budget of just $52,000.

“It is the pinnacle of my education at Texas A&M and the greatest thing I’ve ever done in my life,” said Natalie Marshal, leader of the powertrain team and mechanical engineering senior.

For the 2014-2015 academic year, the group was split into five basic sub-systems: aerodynamics, chassis, electrical, powertrain and suspension.

“From extensive studies using lap simulation software to see variations with change of weight, torque, transmission ratios, power curves and general intuition on how things would actually work out on the track, we chose the 600 CC 2008 Yamaha-R6 Engine,” Marshal said, describing the team’s decision in choosing an engine.

Katherine Letourneau, a member of the chassis team and mechanical engineering senior, described the theme of their project.

“The theme of this year’s design was ‘the driver’s car,’ where the focus was on making things more ergonomic and optimized for the driver,” Letourneau said. “The intensive driver training program at A&M helps us to work with the best of drivers and so most of our designs are justified with their comfort in mind. A lot of schools spend over $100,000 to compete with a lot of third-party designs, but most of the stuff we’ve got is either made in-house or designed by our engineers.”

From software design to part fabrication, students custom-engineered the race car and reduced production time and costs.

“We bought most of our stuff from eBay or Amazon. For example, microcontrollers for our indigenous data acquisition system, where we devised our own network protocols,” said Ziam Ghaznavi, electrical team member and mechanical engineering senior. “This gave us increased flexibility and scalability with the sensors we use and also brought our costs down from $1,500 to $300.”

Most of the students had no prior experience with a project of this scale or technical depth. Interns from the Mays Business School also assisted the Aggie race car team, which hopes to expand to other competitions by increasing collaboration with other departments.

“It is their car — the seniors get credit for their car and this is one distinction we take pride in,” said project manager Jeff Brown.

The Aggie race car team has won five championships in the last 15 years and this year’s team will put its race car on display at 5 p.m. Friday at the Student Recreation Center for the Red Bull Paper Plane Contest.