Beneath a roaring crowd 100,000-strong lies an engineering marvel — Kyle Field.

The stadium’s façade changes are easily seen with a glance up at Texas A&M’s skyline, but there is much more than meets the eye. Kyle Field has received upgrades throughout its structure as engineers addressed several of the building’s challenges with 21st-century solutions.

Kyle Field’s stats are on par with the offense it hosts — 18 million pounds of domestically produced steel, combined with close to 40,000 cubic yards of concrete, now fill out the stadium’s size. More than 1.5 million man-hours have been clocked from the start of renovation to July 2014, and the crew is still going.

The engineering team faced several design challenges with this renovation due to Kyle Field’s construction past. The stadium has gone through three previous construction projects, and changing construction practices meant a series of upgrades were necessary.

“Parts of Kyle Field were added in 1968, 1978 and 1998, and construction processes have evolved,” said Greg McClure, Manhattan Vaughn project director for Kyle Field development. “What might’ve been acceptable in 1968 isn’t acceptable now.”

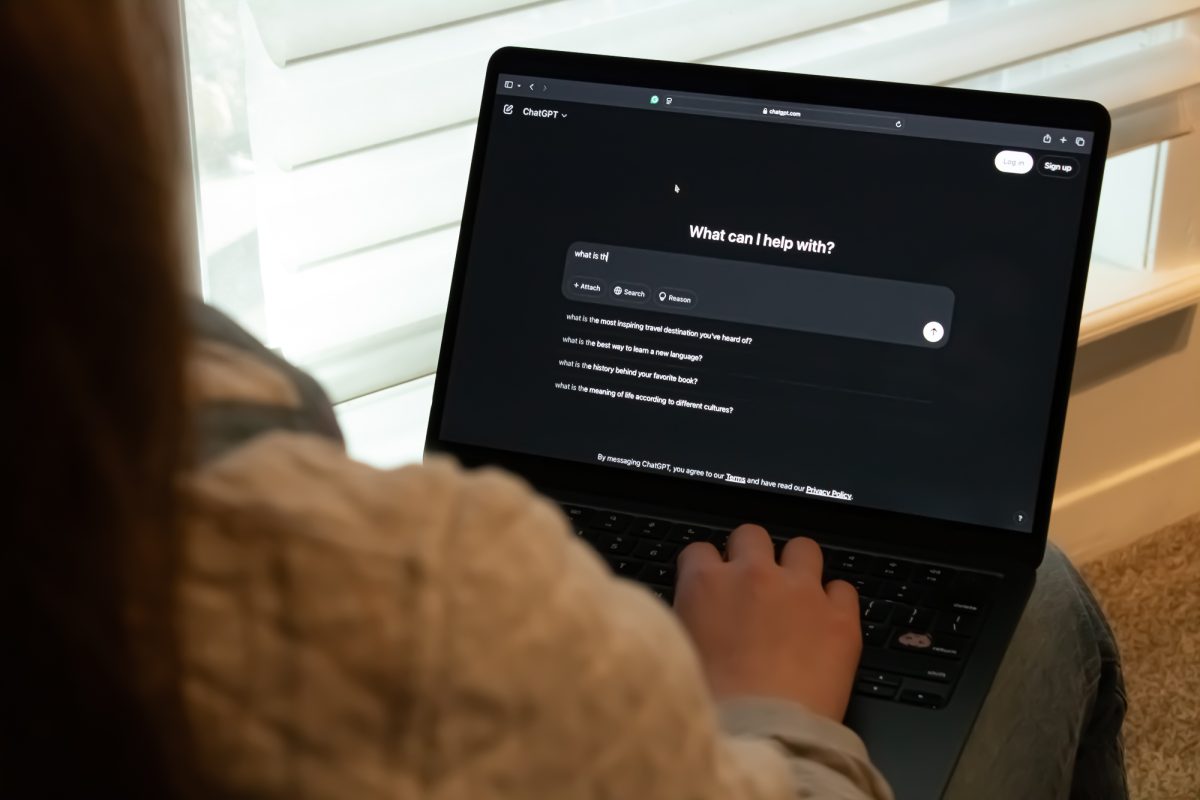

Perhaps the most unique factor that sets the current construction apart from its predecessors is the technology available to aid design. Engineers now model Kyle Field’s construction with design software, but their designs can build on an exact digital replica of the stadium — laser technology allows the team to “scan” Kyle Field, upload the data and interact with it digitally.

“We’re constantly in a 3D modeling software called BIM, or building information modeling,” said Jim Cuddihee, senior superintendent with Manhattan Vaughn. “We can take a laser scanner, set it out in the building and create a 3D image. On the computer we can walk through the building, revising the steel and observing its interaction with the concrete.”

All structures account for a certain degree of movement, and Kyle Field is no exception. As students sway back and forth during the Aggie War Hymn, they’ll notice that the east side is now stiffer than the west, since Phase I incorporated additional steel support with concrete. The crew poured roughly 100 shear walls on the east side to support the backside of the existing second and third decks.

Cuddihee said the redevelopment team considered the needs of the 12th Man by adding additional concession stands and restrooms. The preparation even included a test that workers call the “super flush” — all the bathroom facilities are simultaneously flushed to ensure the plumbing is ready for max capacity.

“You get a bunch of people, spread them out and flush all the toilets, urinals, sinks, everything, within seconds of each other,” Cuddihee said. “Typically you don’t have that during a game. It’s really to make sure you have the capacity to cover 70,000 people going to the restroom at the same time.”

Kyle Field’s designers had to weigh the stadium’s aesthetics and durability against its engineering constraints. All floors are finished with epoxies that need little care over the next 18 years, and the tiles are a tougher quarry material instead of porcelain. The 2.1 million exterior bricks are inlaid to an eight-inch thick wall of concrete and sealed, making it essentially maintenance-free.

“I was born and raised an Aggie, and the exterior façade takes the stadium from a 70s look to a very ornate building that enhances the campus,” McClure said.

Phase II begins Dec. 14, when the entire west side will be brought down in an “engineered collapse.”

“It’s amazing how they do it,” McClure said. “It isn’t ‘go out and blow it up’ — it’ll fall exactly where [the subcontractors] want it to fall.”

A safety perimeter will be in place that day, so the closest one can be to watch the implosion will be from the West Campus Garage.

Since the project’s start, several A&M students have worked for Manhattan Vaughn as interns and hourly employees. They’ve been involved in everything from project engineering to writing contracts and managing subcontractors.

Colin Lane, construction science senior, said it will be cool to share his experience with his grandkids one day.

“I’d tell them we stepped foot in every nook and cranny of this stadium,” Lane said. “A lot of hard work and sweat went into it, but a lot of good memories, too.”

For Tyler Killion, construction science senior, interning combined two of the things he loves.

“I grew up in a family of Aggies, and I’ve grown up in a family of construction people,” Killian said. “I got to put my two favorite things together.”

Kyle Field: engineering marvel

September 24, 2014

Photo by Tanner Garza

Eighteen million pounds of steel and 40,000 cubic yards of concrete have been added to Kyle Field in Phase I of construction.

0

Donate to The Battalion

$2790

$5000

Contributed

Our Goal

Your donation will support the student journalists of Texas A&M University - College Station. Your contribution will allow us to purchase equipment and cover our annual website hosting costs, in addition to paying freelance staffers for their work, travel costs for coverage and more!

More to Discover