In an energy landscape where there is growing public and corporate support for ‘green’ energy alternatives to traditional sources, research by current and former Texas A&M students and professors seeks to provide a solution.

The MixAlco process, a term originally coined by Mark Holtzapple, chemical engineering professor, uses bio waste as input and through a fermentation process, akin to yeast fermentation in alcohols, where biomass is converted into useful fuels and chemicals. Holtzapple said the process is almost identical to what happens inside the stomach of a cow.

“It’s like a giant stomach of a cow,” Holtzapple said. “You put biomass in, anything that could rot outside, and in an environment similar to the stomach of the cow it turns it into vinegar and similar products. That’s what happens naturally and we just want to scale it up to an industrial size.”

This process yields useful organic acids ranging from two to six carbons, which can then be converted into a variety of very useful chemicals ranging from alcohols, esters and ethers through well known chemical processes. Once these useful organic acids are recovered from the process, there are a whole variety of useful products that can be made.

“The idea is that these organic acids are key intermediates … now the power of traditional organic chemistry is available to you now, “ Holtzapple said.

These acids are typically made through petroleum and are responsible for a very wide array of chemical products. Products can be utilized in several industries such as food preservatives, lubricants, coatings, animal feeds and fuels. Through the MixAlco process, it is possible to obtain very useful organic acids without using chemicals that could potentially be harmful to people and the environment, according to Holtzapple.

“Unlike the petroleum processes, dangerous or harmful chemicals are not used therefore there is a value added,” Holtzapple said.

While these valuable acids are currently the desired product from the MixAlco process, eventually the idea is to move over into fuels. One of the companies that has stemmed from this research is Earth Energy Renewables.

Cesar Granda, Class of 1998 and chief technology officer at Earth Energy Renewables, said for now, the main market is for these acids.

“We will stay in the chemical stage as long as we are making money … from those acids we can make many types of chemicals that are very valuable … when you add everything up there is a potential for over a $500 billion market,” Granda said.

Granda has been doing research work with Holtzapple since his days as an undergraduate and has been working on the MixAlco process for more than a decade. While he said he does see a future in biofuels, he added the company will not make any big leaps towards fuels until the timing is right.

“Eventually of course, I think the vision is to go to biofuels once we grow pretty large,” Granda said. “The idea is to take smaller steps and allow the company to become profitable before we scale up … many people in the biofuel industry were trying to take large scale up and it didn’t work out.”

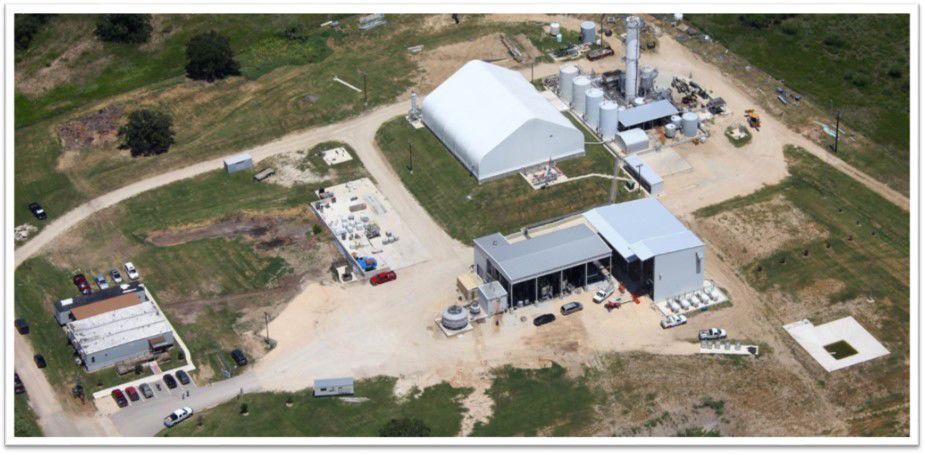

According to Holtzapple and Granda, a pilot plant for this process is scheduled to be completed this summer and if things go smoothly, a commercial plant will be built the following year.

“They have a pilot plant that is demonstrating the newer version of this technology, that should be done in early summer … which is currently only partly operating then the plan is to build a commercial plant,” Holtzapple said.

An additional aspect of the MixAlco process is its environmental impact, according to Holtzapple, who said global warming and pollution are relevant issues to be considered, but even if there is a move away from petroleum based energy, it must find a way to use the current energy infrastructure already in place.

“Once you get [biomass] to the refinery, which could be a regular old refinery they installed equipment to handle it … there is gonna be some difference in the equipment for sure, but there is gonna be a lot of overlap,” Holzapple said. “For example, if you want to go go uphill energetically, you have to put hydrogen into the molecule, well guess what, every oil refinery makes hydrogen from natural gas. So we could use the hydrogen you are already making … I happen to be a big believer in global warming … we may not use oil anymore but we have all this equipment there … the idea is to salvage as much of the infrastructure as you can.”

Since the input to this process is organic waste rather than than a well with a finite amount of oil, the energy derived from this process is sustainable unlike the petroleum based energy, according to Holtzapple.

“As long as the people of Bryan-College Station and beyond keep producing organic waste, it’s gonna be there,” Holtzapple said.

Development of this research is far from over, and one A&M student researcher is working on a new technique that may greatly increase the yields of the process. Tennille Faber, chemical engineering sophomore, does 15 hours of research a week with Holtzapple and is working on a new process which involves grinding the biomass in order to increase yields this is called the “co-treatment” process.

“I have a control group and an experiment group; the experiment group is I’m grinding [the biomass] … and our hope is that there is a jump in acid concentration … and has the potential to remove about 20 to 30 percent of the costs,” Faber said.

The MixAlco process: Green energy for the future

February 26, 2018

Photo by Courtesy

Mix Alco

0

Donate to The Battalion

$2790

$5000

Contributed

Our Goal

Your donation will support the student journalists of Texas A&M University - College Station. Your contribution will allow us to purchase equipment and cover our annual website hosting costs, in addition to paying freelance staffers for their work, travel costs for coverage and more!

More to Discover