Engines are typically associated with cars, but researchers at Texas A&M are making strides in engines across many different industries, from oil and gas pipelines to agriculture irrigation systems.

The Advanced Engine Research Lab, headed by mechanical engineering faculty member Tim Jacobs, is working to improve engines by solving the trade off of emissions and efficiency.

“The three key things we focus on are the performance of the engine, the efficiency of the engine and the emissions that the combustion process results in,” Jacobs said. “We are trying to maximize performance and efficiency while minimizing emissions or at least the impact that the engine has on the environment.”

Jacobs’ lab researches low-temperature

combustion, a type of combustion process that runs around 800 degrees Celsius cooler than a normal engine.

“The goal of this concept is that it avoids emissions formation, but also relies on some of the energy benefits that we get by having the combustion take place at a low temperature,” Jacobs said.

Low-temperature combustion is useful because it helps “defeat the famous diesel engine problem of the soot-NOx tradeoff,” said Tim Kroeger, a mechanical engineering graduate student in the lab. NOx are nitrogen oxides that may contribute to ozone formation.

The “soot-NOx” tradeoff is a “Catch 22” in any engine design — NOx formation can be reduced by not allowing fuel to mix with air in the engine chamber, but this causes more soot to form, leading to more smog. Engine designers deal with this public-environment health tradeoff with conventional engines, but the low-temperature combustion design of this new engine mostly eliminates the tradeoff.

“Low-temperature combustion is unique because it gets a lot of premixing, so it won’t make soot,” Kroeger said. “The fuel in there is well mixed when it burns, so you don’t have much soot. But because the temperatures are so low, it’s basically chemically impossible for there to be many nitrogen oxides.”

In order to minimize emissions while still maintaining a high level of efficiency, Kroeger is coupling this strategy with another process called low-heat rejection. Low-heat rejection is essentially reducing the heat loss of the engine, which can potentially increase the engine’s efficiency.

“If the coolant temperature is higher, the walls are, in turn, hotter and so there is less of a driving force for heat transfer,” Kroeger said.

Another area of work the AER lab is pursuing is an understanding of the effects of variable-fuel composition. This research focuses on engines that work in the massive oil pipeline network.

“In the oil industry, there are compressor engines every 20 miles or so that compress the gas and push it through the pipeline,” Jacobs said. “The way that those engines operate is by pulling a small amount of gas from the pipeline and using that to power the engine, but since you are pulling pipeline gas, there is not a lot of control over the components that make up that natural gas, such as methane and ethane and propane that are the species of natural gas.”

Sometimes difficulties arise with larger engines because of their size, said Jacob Hedrick, a mechanical engineering graduate student working in the lab.

“These are really big engines, like a couple of stories tall when you are standing next to them,” Hedrick said. “So you can’t just put one in a lab and run variable gasses through it, so you are kind of at the whim of whatever is running through the pipeline at that time.”

These huge engines are costly to repair and can produce massive amounts of pollutants, so it is crucial to address problems before they happen, said Hedrick.

“By predictively running the engine in a computer, you can test various compositions that you might not normally run the engine,” Hedrick said. “You can then use that in the engine control and control the engine away from producing the emissions and towards being more efficient.”

A&M lab drives research behind engine catch-22

March 27, 2016

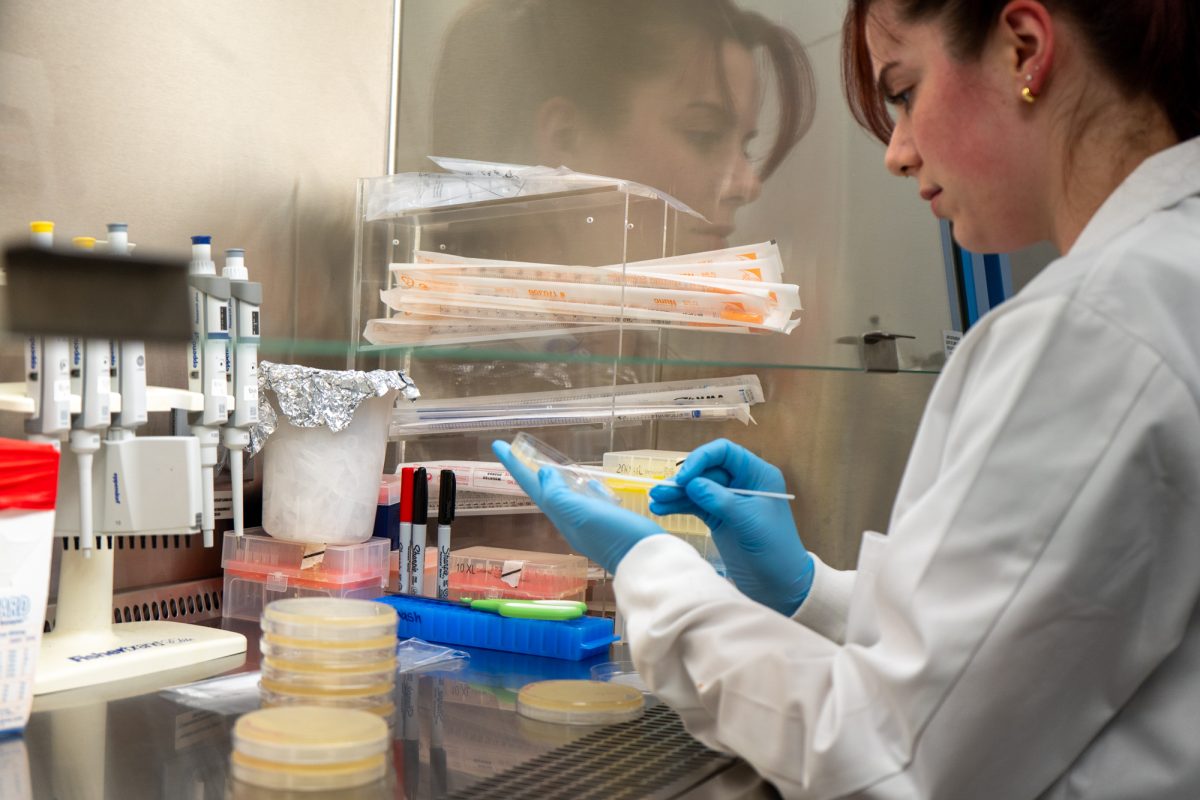

Mechanical engineering graduate student Jeff Brown works in the AER Lab, where researchers are developing a new engine design.

0

Donate to The Battalion

Your donation will support the student journalists of Texas A&M University - College Station. Your contribution will allow us to purchase equipment and cover our annual website hosting costs.

More to Discover