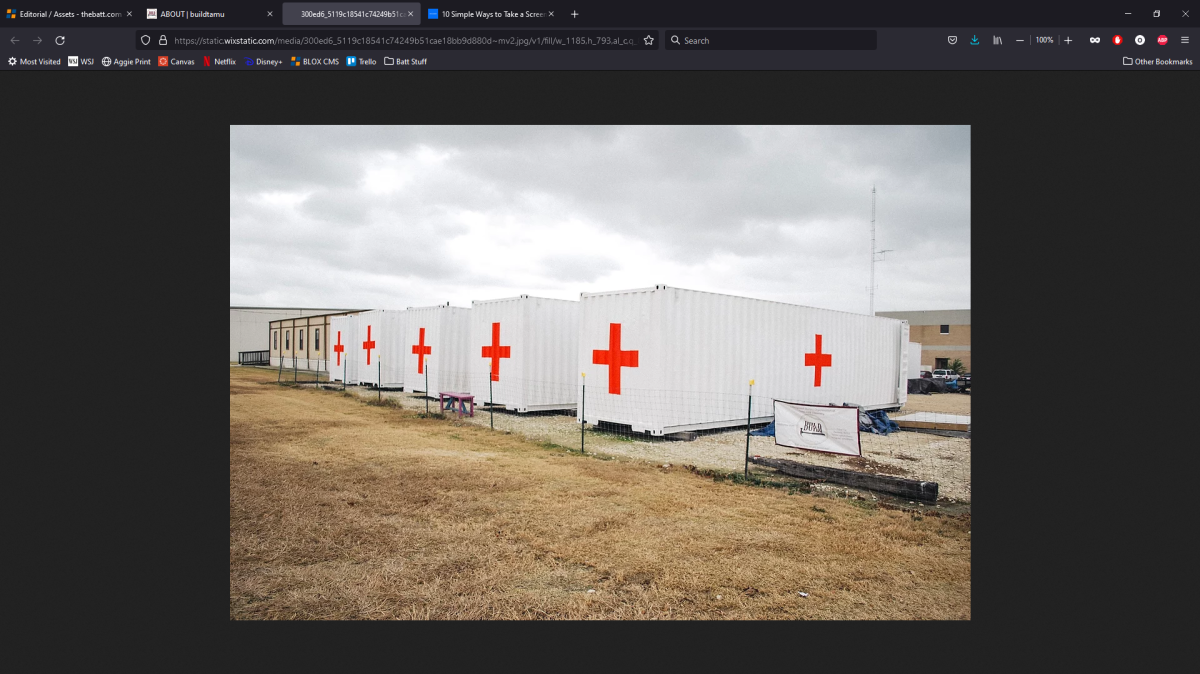

Texas A&M BUILD strives to bring unity on campus through the creation and donation of medical clinics made from storage containers.

The student-led organization was formed in 2013 by two students in the Corps of Cadets who saw a lack of bonding opportunities involving construction projects after the collapse of Bonfire. Since being recognized by the university as an organization, members continue to use construction projects to fuel student connections. The ongoing project the organization is known for converts ordinary shipping containers into fully functioning medical clinics that are then shipped off to different locations in need.

With the creation of the organization, senior biomedical sciences major and BUILD chief financial officer Micah Zimmerer said the intention was to bring back the same energy Bonfire once had through physically demanding projects to help the community.

“That’s how they brought it up to attention and tried to get the work started,” Zimmerer said. “What we do now is convert huge 40-foot shipping containers into medical clinics. We install everything from electricity to plumbing and then ship them around the world. So far since 2013, we’ve shipped 34 clinics to 20 different countries.”

Since joining BUILD his freshman year, Zimmerer said his appreciation for the projects and the organization as a whole has grown after seeing how impactful the finished medical facilities can be.

“I really didn’t understand the whole concept of it and how much it could impact me and communities around the world,” Zimmerer said. “At the end of the semester, we had our end of the year gala, and that’s when someone who had been to one of our clinics spoke about it and how important it was. That’s when I figured out how important it was to me, and that’s kind of why I kept growing into this organization.”

Throughout the semester, Zimmerer said members worked on projects at a construction site on campus.

“From 9 a.m. to 7 p.m., Monday through Friday, there’s always somebody on the build site, typically around 10 people at one time,” Zimmerer said. “Students [not affiliated with BUILD] are also welcome to volunteer to help at the site.”

Senior industrial engineering major and BUILD chief operating officer Nick Janzen said he feels his time in BUILD has truly reflected the mission of the organization’s founders, by helping him get to know other Aggies.

“I joined BUILD in 2019 as a student supervisor. They’re the ones who connect volunteers to our mission,” Janzen said. “ This year, I’m serving as the chief operating officer. That basically entails managing the project from start to finish, sourcing materials, managing construction, making sure that the project gets done. It’s been great so far.”

For the medical units, Zimmerer said the entire process of converting the containers takes about 10 weeks from start to finish.

“We start with the containers being completely bare, just like any other ones that you’d find being shipped around,” Zimmerer said. “Over the course of 10 weeks, we build walls, we build doors, we install AC units, we install cabinets, flooring, lighting, everything like that. We have about 2,000 volunteer visits annually or in that 10-week process. It’s a lot of fun.”

Since BUILD’s founding, mechanical engineering senior and BUILD CEO Robin Bowden said the integrity of its mission has remained the same.

“Our main goal is to unite the student body through this project and fill that gap that was left after the Bonfire Collapse,” Bowden said. “The shipping containers are transformed into what we call Texas Aggie Medical Clinics, and each year we choose different non-profits, or NGOs to receive our clinics. This year, we’re actually sending two to Nigeria, one to Tanzania and then the third one is going to South Sudan.”

Bowden, who also started volunteering as a freshman, said working her way up through the organization from a supervisor has taught her about construction and how it can be used for a greater good.

“It’s been a really great way to learn what goes on behind the scenes and all the effort that’s put into each part of the process,” Bowden said. “It’s been super rewarding, and I’m thankful to be CEO this year.”