Texas A&M researchers may have developed the next step in facial reconstruction — a foam that could one day be used to treat skull abnormalities.

Student and faculty researchers in the Dwight Look College of Engineering have developed a polymer foam that could be packed into a skull deformation after facial reconstruction surgery to kickstart the healing process. The foam came about after several years of biomedical research, and several challenges remain before its operating room use.

Melissa Grunlan, biomedical engineering associate professor and the project’s research advisor, said the foam could be used as a sponge-like substance that can be packed into a deformation to help start the healing process.

“This is basically a foam that a surgeon can treat with some warm saline and then he or she can press it into an irregular defect,” Grunlan said. “As it cools it becomes hardened and healing can start to take place.=”

The foam’s research began several years ago as part of a doctoral student’s dissertation work. It eventually became graduate student Lindsay Nail’s responsibility, who continues it today.

“Undergraduate students and I work with this scaffold, from synthesizing the polymer used to forming the actual sponge-like foam, to testing the foam’s various properties,” Nail said. “Currently, we’re working to tune the scaffold material’s properties to achieve the optimal rate at which the scaffold would be resorbed by the body.”

Grunlan said additional steps are needed to refine the material’s physical traits. Questions remain as to how fast the polymer will be replaced by the wearer’s cells and how practitioners will react to the new technology.

“We also want to align with surgeons or veterinary surgeons to work with them to ask, ‘What would you like to see designed into this material?’” Grunlan said.

Jessica Reinhard, biomedical engineering senior and research assistant to Nail, said this development is important because of the difficult nature of skull abnormalities.

“This is really useful for our research because not all facial defects are the same,” Reinhard said. “So we’re able to heat up the foam, fit it into the defect and cool it to hold the shape.”

Reinhard said her role includes the synthesis of the material.

“I’m very involved in the actual creation of the foams we make for facial reconstruction,” Reinhard said. “It’s really awesome to see the beginning to end of a synthesis and see the final product of a material.”

Grunlan said the research provides a way for students to gain important experience for graduate school and professional careers.

“I’ve had a number of students who’ve worked in my lab who then go on to graduate school themselves and they’re just going to be way more prepared for what lies ahead,” Grunlan said. “And then beyond school, when they go into their careers, they’re just all-the-more prepared.”

Reinhard said this research enables her to develop important skills that she may need in the future.

“Research has given me the opportunity to learn and grow as a scientist, to be creative and think outside the box in problem solving,” Reinhard said.

Grunlan said the development of this material is a display of the prominent research being conducted at Texas A&M.

“It highlights the important research that’s being done at Texas A&M,” Grunlan said. “That we’re doing things here that are going to make a real impact on people’s quality of life, and that it’s done by students who are training to be leaders in the field.”

Researchers develop facial reconstruction foam

October 6, 2014

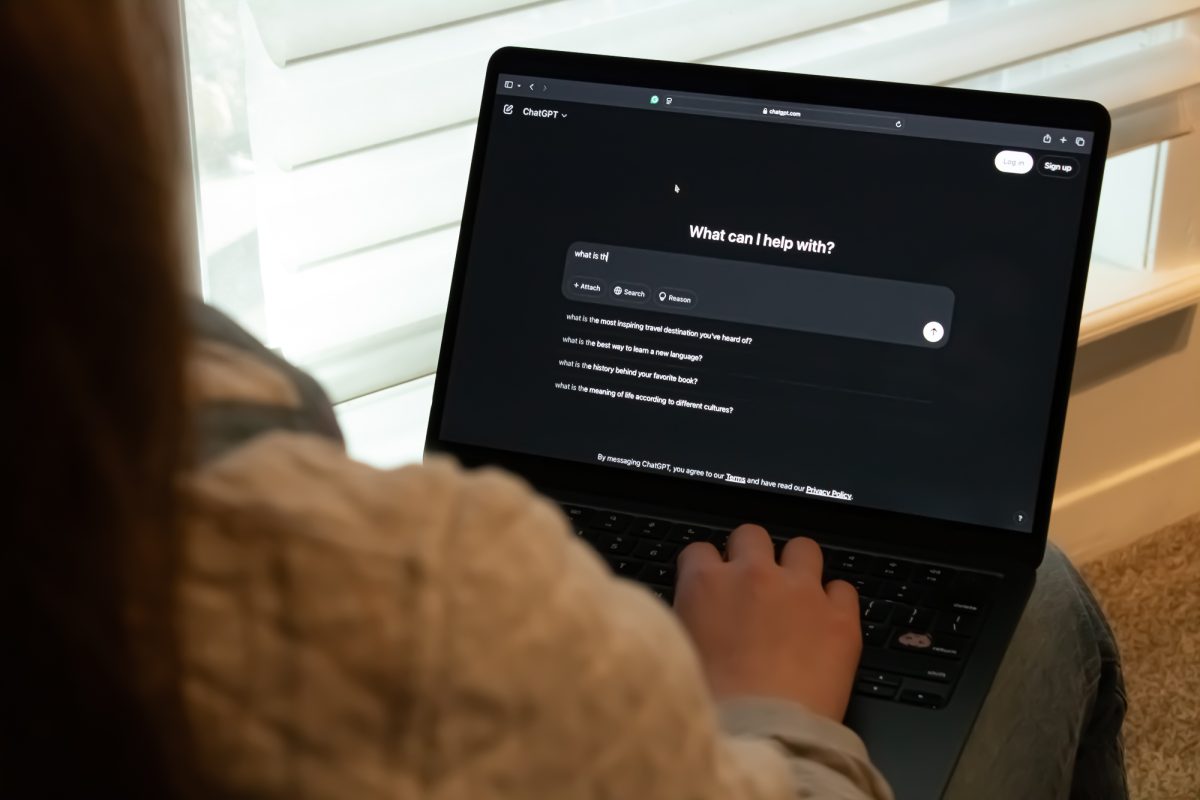

Photo by Sarah Lane

Biomedical engineering associate professor Melissa Grunlan (left) and biomedical engineering graduate student Lindsay Nail work on facial reconstruction materials in the Emerging Technologies Building on Monday. afternoon.

0

Donate to The Battalion

$2740

$5000

Contributed

Our Goal

Your donation will support the student journalists of Texas A&M University - College Station. Your contribution will allow us to purchase equipment and cover our annual website hosting costs, in addition to paying freelance staffers for their work, travel costs for coverage and more!

More to Discover